This page is an archive of all 4123 related news since June 2001.

A Small Update – October 2021

It’s been a while since our last website update, so here is a brief one to bring us up to date. Like many other restoration projects, and due to the pandemic, we have unfortunately lost almost a year’s worth of progress due to the lockdowns, restricted access, and some of our members having to isolate. However, some work has continued, with some highlights as follows:

Tender.

The tender is the prime focus of our attention, and in particular the construction of the new chassis. The structural riveting of the chassis is now essentially complete, with only a few of the 961 rivets still to do once it has been turned ‘right way up’, which will happen when we re-wheel it. In readiness for this, most of the recent focus has been on machining the new axleboxes and weld-repairing and skimming the hornguides prior to setting them up on the frames and riveting them into position, with Carl H, Lee W, and John F undertaking much of this skilled work.

To allow us to machine the inside faces of the axleboxes, we have acquired an 18” shaping machine, and with the assistance of Gillan H this was brought to the railway earlier in the year and cleaned-up by the mid-week gang to make it ready for action. Once we’ve made some room for it, it will come into our workshop, and we can complete the axleboxes and also machine the bearing blocks prior to whitemetalling.

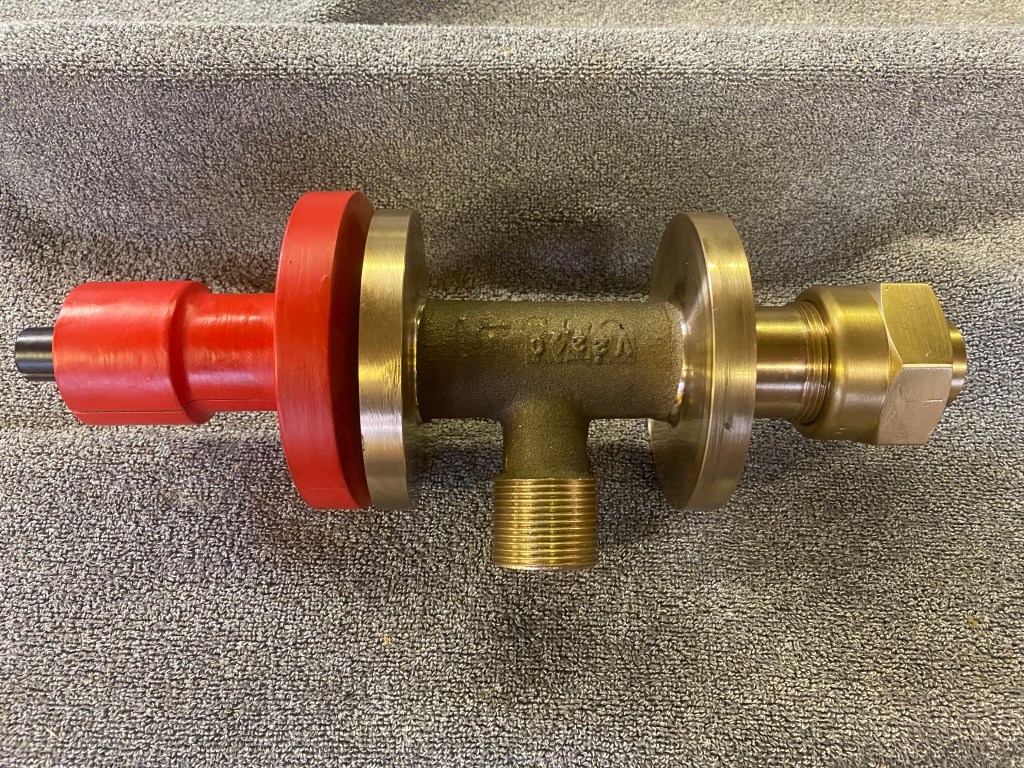

Work has also focused on repairing and fitting up the remaining underkeeps, with the refurbished spring hangars having been riveted on earlier in the year. With the machining of various gunmetal castings by James F in his home workshop, all bar one of the steam fittings needed for the tender are now to hand, with the final item being the buffer beam steam heat valve, for which we hope to source a casting from the Severn Valley Railway, having already been given a drawing by the British Enginemen Steam Preservation Society at the Colne Valley Railway, who are restoring a Black 5.

Loco

The loco is generally on the backburner, although when they have not been engaged on other tasks our mid-week group (Patrick H, John T and Alans B & M) have gradually and literally been chipping away at it, by removing the debris in the cylinder casting/smokebox saddle. Some machining work on castings has also been carried out, with the prime focus being on various fittings associated with the Loco’s steam brake system. We have recently visited sister loco No. 4027 at the Vale of Berkeley Railway at Sharpness and have struck up a good relationship with their new team, following a change of personnel. 4027, being a complete loco, is a very handy point of reference for us, and being only 25 miles away from Bitton means we can easily visit for the purpose of taking measurements and seeing how things are arranged on the chassis. On the ‘admin’ side, Patrick has been working his way through photographing the large number of drawings we have on loan from the 44422 loco group, so soon we will have a full set of electronic drawings, which will essentially comprise all the available 4F drawings which are known to exist – a very useful resource.

PMV S1153S

Followers may recall that we purchased former Southern Railway Parcels & Miscellaneous Van No. S1153S some years ago, this being used as one of our main stores vehicles. Preservation of wooden bodied vehicles without covered storage is something of an endless task and a battle against the elements, and in the past 18 months, the PMV has had quite a lot of attention, including replacement of some rotten planking and window frames. It has also had repaint into early 1950s BR Crimson livery by Dave I – and what a cracking job he’s made of it. One side of the van has now been completed including being fully lettered in authentic style, and attention is now being turned to the other side. At some point we’re going to need to deal with the roof, which has sprung a few minor leaks!

Summary of 2012

The year has actually been something of a mixture as regards progress: Some of it has been in the forward direction but there has also been a certain amount of ‘treading water’: Before turning to the loco itself, it is probably worth pointing out that in line with our strategy of being better organised as a group, and dovetailing in the with the overall needs of the site and AVR trust, a significant part of our efforts have been devoted to organising and sorting of our components, tools and raw materials. As regular visitors to the AVR will be aware, there is much material scattered about the site from various live and historic projects and the 4F has contributed to this collage of industrial artefacts.

Much of this material, if we are brutally honest, is really only good for scrap, and the 4123 has benefitted from the tidying up and disposal of many redundant items which does, apart from the benefits of having a tidier site, make a modest contribution to our funds. With the arrival of a 20ft shipping container and coupled with our existing small fleet of rail mounted vans, we now have enough storage space for tools (light and heavy) / loco parts (light and H.E.A.V.Y) and consumables, and these are broadly speaking in a much better state of organisation and cataloguing. We still have some work to do in this regard, but there is light at the end of the tunnel and we hope that this effort has resulted in improvements for all users of the AVR site. We have also made improvements to the drainage and floor surface in our workshop, in order to alleviate significant flooding during the heaviest rains. This work has also addressed an historic issue with the proper drainage of the SW corner of the goods shed (i.e. there wasn’t any) which will also be beneficial to the railway in the long run.

Turning now to the loco and forward progress, you may have noticed that this has now been moved into the body of the yard on ‘No.2 road’, and for the first time in many years is now under-cover – albeit only a temporary sheeted scaffold building. Although basic, this does allow some work to continue in (almost) dry conditions, and although the aim is primarily to preserve the loco from the elements we hope to take further advantage of this in the coming months as we have greater access to the loco for volunteers to undertake various jobs; preparation for riveting the cab, removal of the smokebox and dragbox, and fitting of the new buffer beam once the stiffening U sections have been machined on the horizontal milling machine.

Other work on the loco has seen the start of machining on these stiffening U sections, and bending of the new dragbox and other plates by Accurate Section Benders in the midlands, and these should be delivered to us soon. We have also carried out visits to the custodians of sister loco no. 4027, at the Gloucester & Warwickshire railway which has yielded much useful info and dimensions for components which are missing and for which there are no drawings (drawings are everything in loco restoration). We are extremely grateful to the 4027 for their willing help and free access, and we have hopefully been of assistance to them with the provision of a new set of fire doors for the NRM loco.

The majority of demonstrable progress in 2012 is the effective completion of the new drag boxes for the tender. These are large and heavy steel fabrications (actually riveted) which are now the two prime sub-assemblies required for the erection of the new tender frames. Whilst they are not particularly complicated items, they are big and heavy and thus a considerable amount of work has been required to get them to this stage and they are now ready to trial fit in the frames. Many holes have been drilled, and there is hardly a member of our team who has not learned to use the mag-base drill and during the peak of drilling activity, many visitors have also been invited to lend a hand. (Skills have been learned by ages 7 – 67). Elsewhere on the tender work continues on the overhaul of the various fixtures and fittings which make up the chassis, and various flat pack sections for the new tender tank have been made are in storage.

Our prime aims in 2013 are to undertake remaining drilling of the frames and then trial assembly – thus it will begin to look like a tender again rather than an industrial version of an Ikea flat pack. We also hope to have some exciting news relating to the construction of the tender tank later in the year.

16th May 2010

After many hours attempting to repair the original tender frames, we decided that enough was enough and it would be altogether easier, and better in the long run to start again and make new… So we have recently taken delivery of brand new outer and inner frames.

These were plasma cut for us by Precision Profiles of Bristol, and a very nice job they made of them.

In addition to the frames themselves, there are many fittings mounted on the frames which need to be re-furbished for re-use; Horn guides, spring hangar brackets, under keeps etc, not to mention the numerous lengths of angle and brackets which make up the structure of the frame. Anything useable has been recovered from the old frames and is now being overhauled.

Making everything ready for assembly. Horn guides and spring hangars removed from original frames offered up for inspection. Some work to do on all these before they are ready to be re-used. New front buffer beam in red primer can be seen on the top right of the picture – drilled and ready to fit. Lots more holes to drill in the frames in the very near future…

Some of the horn guides get their first coat of paint in many years. Actually there is not much wear on these horn guides which means less machining and makes life a little easier

It was necessary to make a new under keep as one of the old ones broke in half when it was removed from the original frames. Here is a new one having the finishing touches machined on…

Because, like everything else on the tender, the drag boxes are rotten to the point of scrapping, we have to make new. There are three drag box sections at the rear of the tender, and two at the front. These are of unusual dimensions which means that they cannot easily be made from modern structural steel section sizes, so they have to be fabricated as specials… These ‘U’ sections were formed for us by Accurate Section Benders of the West Midlands. Five pieces total for the tender, and two long ‘U’ sections for the loco which are located immediately behind the front buffer beam.

New tender drag box sections (on the left) and loco front buffer beam backing pieces (right) awaiting collection from Accurate Section Benders. These need further fabrication work, machining and drilling before assembly…. more on that soon hopefully.

24th April 2009

Since the last update we are pleased to report that the old wooden box van has been sold, and has now left the AVR. We wish the new owners well with its restoration, and look forward to seeing it completed sometime…

The majority of work is concentrating on the tender, with steady progress being made. We have just taken delivery of two new coil springs for the ‘mini-buffers’ between engine and tender.

These springs were made for us by the Tested Spring Company Ltd and are a re-design in round wire, as opposed to the orignal rectangular section. As with many loco materials the correct rectangular (trapezoidal actually before rolling) section material is no longer available unless you want to by a whole sheet of the stuff and have it machined down. This being cost prohibative led us down the road of re-designing the springs in round section wire….

Elsewhere, the tender wheelsets have been de-rusted, cleaned and primed and are now ready to go off site for tyre and journal turning. The tyres are thick enough to take another turn, and there is a small amount of cleaning up to be done on the journals to get them back into round and provide a nice bearing surface.

We hope to get the wheels away before to long, and are just awaiting final quotes from various outfits… like many things in the preservation world, these are not always as quick to arrive as you may imagine…

Elsewhere, work has concentrated on platework for the tender chassis. One small task was the preparation and machining of four small sections of 1″ plate, which will be let into the frames in the area of the cross stretchers – the original material having corroded very badly in this region.

The two new bottom cross stretchers have now been finished profiled and are being machined ready for fitting (no photo yet). Next task is likely to be commencement of fabrication for the front and rear dragboxes and for which most of the material is to hand. When these are done, and the inner frame plates are ordered, we have all the material for the tender chassis, and it should be a case of starting to re-build it.

Steadily we move forward towards a re-built chassis…

Restoration Update – 5th Jan 2009

Work is ongoing on several fronts:

The Tender springs have returned from overhaul at Owen Springs. Several of the springs needed new plates to replace the cracked originals. We also took the opportunity to have a new spare spring made. The chances are one is going to get broken at some point in the future…especially on some of the dodgy track which is to be found in preservation…

With efforts primarily focussed on getting the tender to “Rolling chassis” stage, attention has now turned to the tender wheelsets. Measurements indicate that the tyres and journals have another ‘turn’ left on them, so we are moving forward with a view to getting the tyres turned in 2009. To this end, a start has been made on cleaning up the wheels so they can be painted prior to turning.

Work is ongoing on the pattern for the injectors with core box and body being advanced. It’s a complicated pattern, so it’s taking a little time to get right…The pattern for the tender handbrake and water scoop stanchions is also nearly completed. Delivery of “suitcase” clips for the rather large core box delayed things somewhat.

Elsewhere – parts continue to arrive for the loco and tender, latest being the first casting for the vacuum drain value body and castings for the tender mini buffer guide bearing block bushes.

Machining work has continued on the tender mini buffer bearing blocks. This is very much an “as and when” task which is fitted in around other things and is dependant on the machinist’s time and also being able to get on the Horizontal Mill….(James B).

The Tender front “Buffer beam” has been finish profiled, fettled and painted, and now just awaits drilling prior to assembly. This was the last major item of platework for the tender chassis, with the exception of the inner frame plates, which hopefully will be ordered in Q1 2009. Once these are received and drilled, attention will probably turn to fabrication of the new front and rear dragboxes. Then we have the full kit of parts to start actually REBUILDING the chassis! It will be nice to assemble something for once.

Away from the actual work going on to restore the loco, 4123 was arbitrarily put on a list of “No-hoper” engines by somebody on the National Preservation discussion forum. You can follow the debate and read my response here.

That’s all for now.

Tender Restoration Update – 15th July 2008

The front section of the tender frames is now fitted up and almost ready for welding. To get this fitted up correctly required a good deal of effort to make sure all was square and dimensions correct.

New section of frame plate and top angle being set-up ready for welding. Remains of old plate can be seen in the background.

Elsewhere – parts continue to arrive for the loco. The latest being the first casting for the slidebar oil pots.

Work has started on the pattern for the injectors. This is a complex pattern, but we think it can be made in house…

Brief Restoration Update – 27th May 2008

Pictures here are the “Mini buffers” for the tender which have almost been completed. These have been made totally in house by the London Midland Society.

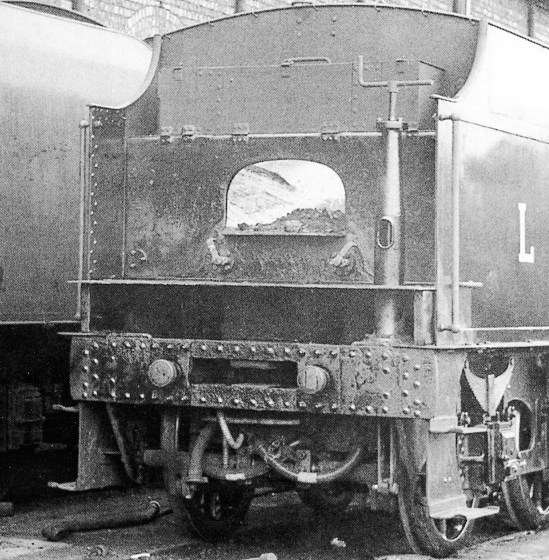

These are the buffers on the tender which you don’t normally see when the loco is in service (unless you look really hard). You can see the heads of the buffers in this shot;

In the above photo, you me be able to just make out the spring on the inside of the front dragbox on the left. We are in the process of sourcing material to allow us to have two new springs made. This is not an easy task, as the correct spring material is 1.25″ x 0.875″ rectangular section and nobody in the UK makes it, and almost nobody uses it any more…. 40 years ago it wouldn’t have been a problem…

Other parts and castings continue to arrive, the latest selection includes; Tender brake shaft trunnion bearings, loco vacuum system drip valve, injection handwheels and drawbar guide plates.

Tender springs have been delivered to Owen Springs of Rotherham for dismantling, inspection and overhaul, as we move ever closer to a rolling chassis for the tender.

More soon…

Photo news – March 2008

The main item of news is that we have recently taken delivery of a new vehicle – former Southern Railway PMV No. 1153. This is to become a stores vehicle for the restoration of 4123.

The London Midland Society took the opportunity to purchase the van from the 35035 Brocklebank Line Association who had been given notice to quit the Great Central Railway, and were rationalising their rolling stock collection.

This is the interior of the van after it had arrived at the Avon Valley Railway, and being prepared for conversion into a stores vehicle

As the van is ‘a runner’ – the opportunity was taken to include it in the AVR’s demonstration goods train which was running behind visiting 7F No. 53809. We were able to give something back to the AVR by helping strengthen the goods train with a genuine SR / BR(S) vehicle.

In addition to the organisation of component parts and materials in the new stores van, restoration work continues, with the majority of activity being focused on the tender chassis.

The front section of the tender frames is completely rotten. It is being replaced with new platework. Here we see the cutting of the frames behind the first hornguide.

This is the new front buffer beam for the tender after being profile cut to shape. The large slot in the middle is where the tender draw bar, intermediate ‘mini’ buffers and safety connection links will be positioned. Since this photo was taken, the ends have been cuts to size and the radius added. The beam is now ready for drilling.

These are the springs from the tender – they will soon be going away for overhaul and re-tempering. At some point in its life the tender was fitted with one odd spring with more leaves that all the others. This will be corrected during the spring re-furbishement.

One of the spring hangar links having been de-bushed and cleaned down. Curiously, this is stamped “SR” which suggests that the tender was once repaired by the Southern Railway, or it inherited parts from a similar Southern loco, or an LMS loco which was overhauled by the Southern – one of the S&DJR 4Fs perhaps?

A selection of tender axlebox bearing plates and spring hangar links cleaned down and ready for re-painting.

Also for the tender chassis – we have just taken delivery of a set of ‘Armstrong’ oiler pads, which keep the axle journals lubricated inside their axleboxes. These were made new by Armstrong Oilers – part of the North Yorkshire Moors Railway

Patterns for other tender components continue to be produced. Two major patterns which are nearly complete are the Tender handbrake and water scoop stanchions and tender tank vent pipes. These will hopefully be sent to the foundry for casting in the near future. We also now have all six wheel bearings cast as we move closer towards a rolling chassis.

The tender wheelsets are presently undergoing assessment to establish whether tyre turning is needed…watch this space.

Loco

Work continues on the acquisition and manufacture of parts for the loco. Various patterns are in progress or ready for castings, including various lubrication fittings and cylinder relief valves. We have also just taken delivery of the adapter piece which goes between the blastpipe leg and the blower ring in the smokebox.

Sits on top of this…the blastpipe ‘leg’. We are pleased to have supplied one of each of these to our friends at the Keighley & Worth Valley Railway to assist in the overhaul of their 4F no. 3924.

More soon hopefully.

April 2007

We have recently taken delivery of piece of steel plate, pre-profile cut, which when welded into position, will form the repaired front end of the tender frames. Also just arrived are two lengths of 150mm x 75mm x 15mm angle – these run along the top outer edge of the frames and are to replace the originals which are totally rotten. The Left hand side tender frame has has all defective holes repaired and re-drilled, and most of the corroded areas have been built up with weld and dressed back to restore them to original thickness.

Pictures soon…

December 2006

Taken delivery of new blast pipe casting – this is a very large casting that fits in the smokebox of the loco and guides the exhaust steam from the steam chest up to the chimney. Picture soon.

Another trip was made to our friends at the Keighley and Worth Valley Railway, to measure up some components of their 4F No. 43924. They are mid way through a heavy general overhaul of this loco, which gives us a great chance to get dimensions for the parts that we don’t have, or where no drawings exist. We are very grateful to the K&WVR for allowing us unrestricted access to the loco.

August 2006

Recent castings delivered include a new pair of loco firedoors, and a small angled adapter piece which sits in the tender coal space and through which the water indicator gauge passes.

Original angled adapter piece – middle/top of picture

rotted by years of exposure to coal dust and salty atmosphere.

Work has commenced on a pattern for the tender handbrake and water scoop stanchions – the originals being cracked and badly corroded.

April 2006

We have taken delivery of seven new tender axlebox castings (six and one spare). The patterns were made from an original axlebox borrowed from the tender of AVR 8F No. 48173, which actually has a 4F tender ex 4422 – confused?

Elsewhere, work continues on the restoration of the tender frames. The intention is to replace the front 1/3rd of the main frames, and a small section at the back, with new steel plate to be welded in, with the remainder of the frames being restorable. All the rotten platework has been removed, and a start made on repairing the worst affected areas with weld. We hope to be in a position to order new material for the front of the frames, inner frames, front and rear drag boxes and external stiffening angle before too long.

October 2005

The tender chassis is almost fully dismantled, the final stage in the dismantling being the removal of the wheel and axleboxes, which took place on 3rd October 2005, with assistance from the AVR diesel crane.

March 2005

With the tender chassis ready to be dismantled, and with workshop space at the AVR severely limited, we have decided to construct a temporary shelter, using old boiler tubes and tarps, to allow us to begin the restoration of the chassis in some kind of comfort away from the worst of the Bristol weather.

July 2004

The tender tank of Fowler 4F No 4123 was cut in half and lifted off the chassis by one of the AVR’s cranes to allow work to continue on the chassis, for which many new parts have already been made. It was necessary to cut the tank in half, as the crane did not have sufficient capacity to lift it all in one go.

In due course a brand new tender tank will be built and fitted to the chassis as part of the ongoing restoration of the engine.

Above photos – Gordon Ashton

7/11/2003

44123 at what is thought to be Gloucester shed in the 1960s. Note the generally filthy condition of the loco, with the exception of the cab side, which some brave soul has attempted to clean.

With ‘background’ work progressing on the loco, the majority of the physical work recently has continued on the tender. We are moving towards having a rolling chassis in the hopefully not too distant future. Key to this is the repair or replacement of the six badly damaged axle boxes. The first step on the road to recovery is to replace the missing axle box lids – being easily removable it is hardly surprising that none were left when the loco was removed from the scrap yard – other Barry island visitors being all too easily tempted to have a souvenir or a few spares for their own engine. After detailed study of lids from other Fowler tender axle boxes and our own boxes, a wooden pattern was produced in house, and hopefully by the time you read this, we will have the newly cast lids machined and safely in storage. Attention will then turn to either the repair or making new of the tender axle boxes. To do this however, we will have to extract one as no drawing is known to exist.

Whilst in pattern making mode, the opportunity has been taken to produce one or two other simple patterns, such as the cylinder drain cock valves and genuine ‘LMS’ pattern coupling hook tommy bar balance weight! (Thanks to John Payne for supplying an original).

Because of the considerable forces involved in pulling heavy freight trains about, many parts of the 4F are extremely well engineered and built to last, and this usually means ‘HEAVY’! No exception are the various cast iron blocks which support the tender front draw gear – they take the draw pin loads and buffing forces between engine and tender and are subjected to much clattering and banging as the loco moves along. What they were not designed for however, is sitting about in a sea-side scrap yard for 25 years. Salt air combined with coal and ash deposits does terrible things to ferrous metal over time, and so we have to make new ones. Many years ago the group had the foresight to acquire some large lumps of scrap cast iron for just such a purpose. These have been carved up into suitable lumps and sawn down to rough size in our big band saw. Finish machining is currently ongoing, and that’s another heavy lump into storage ready for fitting when the time comes.

Speaking of buffers, in the not too distant past our shop resembled a ‘buffery’ (not to be confused with the buffet which is on the station). All the LMS pattern buffers in our possession were pretty much seized solid, necessitating a strip down, clean up and straighten, followed by a rebuild. The amount of energy which can be stored in a set of compressed buffers is considerable – you only have to look at the spring to see that. If you’re interested, ask to see one when next at the railway – you wouldn’t want to drop it on your foot.

On the loco front, in recent weeks and following renewed discussions, we are fortunate enough to have acquired a number of original motion parts from fellow 4F owners at the Keighley and Worth Valley Railway in Yorkshire. There is no doubt that they will fit our engine, as they are clearly stamped ‘4123’ in big letters! Our colleagues at the K&WVR also provided us with a number of other important parts for which there are no drawings. Our thanks go to those in the K&WVR loco dept for their kind help so far and offers of future assistance. We have also been speaking to the 4F group from Cheddleton/Crewe who are currently looking in their stores to see if they have any of our bits hidden away. It is also nice to have the option of looking over both the group’s 4Fs whenever we like, which is something we intend to do soon to continue the information gathering exercise so vital to the restoration of a mainline locomotive.

April 2002

We recently visited sister 4F No. 44027 and 7F 53809 (which has a similar tender) at the Midland Railway Centre, Butterly, to measure up some parts on the tender including the axlebox covers and some water feed fittings on the tank. This will allow us to produce new items, as we do not have them currently and no drawings exist. Thanks to the Midland Railway Centre loco dept for their kind assistance so far.

Jan 2001

Like 34058, work has concentrated largely on the tender (No. 3257) in recent months. Everything above the running plate on the tender is being re-constructed from new to give a whole new tank and upper structure. The original tank is totally rotten, and is wafer thin in places. To maintain the authenticity of the finished article, fully riveted construction is being used and where the original parts are too rotten to be re used or copied, new ones are made from the original works drawings.

The vast majority of the external components for the tender tank have now been made, as have a good number of items below the running plate, including the four sets of steps and two cross-frame stretchers. Jim Frampton (assisted by Lucy) has been working on removing the remaining bits of brake gear mounted on the frames. Jim has developed a highly successful technique of freeing up seized components – he lights a fire underneath them, lets it burn for a few hours, then it all more or less falls apart!

We have recently taken delivery of more raw materials to allow us to start work on the tank internals, including the riser pipe from the water scoop to the top of the tank. The scoop is being retained to maintain the authenticity of the tender, and by the time you read this, it will all have been removed and be well on the way to restoration. All the brake linkages and brake block operating levers have also been removed for straightening, building up with weld to repair any worn areas, and re-bushing with bronze bushes before being put into storage.

The tender frames are in reasonably good condition, but will require some new sections to be welded in at the front, where the amount of wastage is quite severe. The front and rear drag boxes and buffer beams will need to be replaced, as the originals are totally rotten.

The engine itself has been shunted to the very top end of the signal box siding to make more room in the yard, and is now the first thing you will see upon approaching the station on the cycle path from Oldland Common. It is effectively ‘mothballed’, but has not been forgotten, with one of the original cast iron sandboxes recently being repaired and bolted back onto the frames for storage. Work is always rumbling on with smaller items being produced on a continuous basis the most recent of these being replacement lids for the sandboxes which were made after taking dimensions from classmate 4027 at the Midland Railway Centre. Thanks are due to the MRC for allowing us access to 4027.